What Does Tpi Stand for on Saw Blades

When woodworkers are choosing the correct circular saw blade or jigsaw blade, the number of teeth as well as the teeth shape and angle can impact the finish of the cut. This saw blade teeth guide will help you identify what is suitable for different material applications.

TPI explained

TPI is the number of teeth the blade has per inch. If you're looking to cut wood or other soft materials, you'll need a blade with a TPI of 6 up to 20.

For harder materials like metal, a TPI between 14 up to 36 is more suitable.

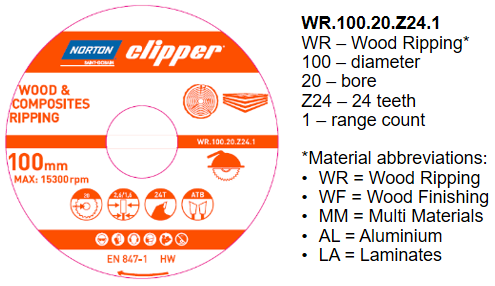

The number of teeth can be found on the blade.

Are more teeth better?

Generally, the higher the amount of saw blade teeth, the better the quality of cut and finishing. If you're looking for a faster and rougher cut, then a blade with fewer teeth will be more suitable.

For example, if you are cutting aluminium or high quality finish when cutting laminate, you will want a higher number of teeth compared to blades for soft wood.

When blades have fewer teeth, they have deeper gullets (space in between teeth) which creates a more aggressive chiselling action. Norton Clipper TCT (Tungsten-Carbide Tipped) blades have gullets with a unique shape compared to standard gullets, which reduces the vibration and noise while cutting, as well as reducing the heat on the steel centre which makes it safer for the user.

The difference between tooth shapes

Not all teeth are the same. Different tooth shapes can affect the working speed and are more suited for cutting different types of materials. Make sure you choose the right type for the application and desired finish.

Common teeth profiles of Circular Saw Blades:

Alternate Top Bevel: This tooth design is bevelled on the top, with every other tooth being bevelled in the opposite direction of the adjacent teeth. Blades with these teeth are easy to re-sharpen.

Alternate Top Bevel: This tooth design is bevelled on the top, with every other tooth being bevelled in the opposite direction of the adjacent teeth. Blades with these teeth are easy to re-sharpen.

Ideal for: Cross-cutting solid woods and veneered plywood.

Recommended blades:

For ripping wood - CLIPPER PRO WOOD RIPPING 160x1,8/1,2x20 Z24 (70184608040)

For finishing wood and composites - CLIPPER PRO WOOD FINISHING 250x3,2/2,2x30 Z48 (70184608109)

Tip: A higher tooth count provides a finer cut.

Triple Chip Grind: The trapezoidal teeth cut first, then the flat top teeth clean out chips and widens the cut. These blades are made for heavy duty cuts and can also be re-sharpened.

Triple Chip Grind: The trapezoidal teeth cut first, then the flat top teeth clean out chips and widens the cut. These blades are made for heavy duty cuts and can also be re-sharpened.

Ideal for: Really hard materials, like coated chipboards (HDF / MDF) and aluminium. This tooth delivers very clean cuts on laminates and non-ferrous metals.

Recommended blades:

For ripping - CLIPPER PRO LAMINATE 160x2,2/1,6x20 Z48 (70184608141)/span>

For finishing - CLIPPER PRO ALUMINIUM 255x3,0/2,2x30 Z80 (70184608139)/span>

Demolition: The cutting material of demolition blades is very complex.

Demolition: The cutting material of demolition blades is very complex.

Ideal for: Cutting poor quality chipboard, as well as wood with loose knots and nails due to its anti-kickback design to add safety. The blades also have a chip limiter at the back of the tooth shoulder that limits the maximum tooth bite for controlling the feed speed to the safe rate.

Recommended blade:

CLIPPER PRO MULTIMATERIAL 190x3,0/2,0x30 Z20 (70184608129)

For added safety, Wood & Composites ripping blades in the larger diameters also use this design. These blades feature big teeth bites (the distance between two teeth), so it is necessary to use these on a machine that has a chip limiter to control the feed speed, to prevent the kickback.

Common teeth profiles of jigsaw blades:

Milled: This design is less finely sharpened and tears the wood fibres rather than cuts. It's more aggressive and results in a faster, but rougher cut. The saw set leaves traces during the movement of the blade from top to bottom, hence delivers a rough cut in the wood.

Ideal for: Metal and denser material as it lasts longer.

Recommended blades:

JIGSAW BLADE HCS 76 T218A (70184608380)

Wavy Set: This wave design maintains surface contact between the blade and the material to avoid jolting and thus ensures a straight cut.

Ideal for: Cutting thin parts, such as sheet steel or plywood.

Recommended blade:

RECIP BLADE BIM 228 S1122HF (70184608357)

Ground: This design creates a sharp edge with a very straight alignment of teeth. The edge of each tooth is perpendicular to the cutting axis, which allows each tooth to work over its entire width to deliver fine, sharp and very clean cuts.

Ideal for: Softer materials, such as chipboard

Recommended blade:

JIGSAW BLADE HCS 100 T101B (70184608371)

Ground Side Set: This design cuts according to the oblique angle of the teeth.

Ideal for: Cutting wood at high speed.

Recommended blade:

JIGSAW BLADE HCS 100 T244D (70184608375)

It's all in the angle

The direction of the blade's teeth, also referred to as the hook angle, are recommended for different material applications. The higher the hook angle, the more aggressively the saw blade will cut the material. This is great for getting through a lot of material fast, especially when you are ripping.

Low (negative) hook angles - those that have teeth that angle backwards (away from the direction of rotation), are good for crosscutting, cutting plywood panels or non-wood materials, such as plastics and metal. If you're cutting plywood, MDF, OSB, laminate, melamine boards and particleboards, then an angle between -2° and -10° is recommended.

Four steps to selecting the right wood blade:

By understanding whether you need a higher number of teeth and the desired teeth shape, this helps you select the right blade to achieve the desired finish on your material. Download the Wood Range catalogue and follow these steps to choose the right blade for your needs:

1. Identify the material being cut

From this, you choose the relevant colour coded section with your ideal product.

2. Which machine will the product be fitted to?

Product information is grouped by machine type, e.g. circular saw

3. Which size blade is required?

Check the specifications of your machine.

Product dimensions can be found underneath each product line when viewing the product in the catalogue, e.g. 165mm with a 20mm bore.

4. Which type of cut do you need to achieve?

A variety of cut types are available, such as ripping and finishing. You can also see the teeth design information in the key specification data underneath each product line.

Download Catalogue

Using the saw blade

When working on wood materials, we recommend wearing a mask and safety glasses, as well as ear protection and gloves during heavy duty usage. It can also be beneficial to use a vacuum extraction unit to remove shavings or debris.

Before using any blade, systematically and carefully check your machine and blade conditions.

If a reduction ring is necessary, please thoroughly check its quality and ability to perfectly fit the bore of your blade.

We recommend regularly (if not after every use) cleaning your blades to extend the blade life and maintain the quality of cut.

To help understand the different types of wood, read the beginner's guide to wood. For further information about wood cutting and choosing the right blade, get in touch with one of our Norton experts.

What Does Tpi Stand for on Saw Blades

Source: https://www.nortonabrasives.com/en-gb/resources/expertise/ultimate-saw-blade-teeth-guide#:~:text=TPI%20is%20the%20number%20of,to%2036%20is%20more%20suitable.